Our new blog post features what automated visual inspection systems are and how their implementation in your workflows can notably improve your business efficiency, no matter the niche you’re in.

With the growth of AI across industries and business domains, computer vision tech has also started gaining traction. To wit, the global visual inspection automation market was estimated at $16.69 billion in 2024, and this number is expected to reach $26.71 billion in 2034, showing a compound annual growth rate of about 12.5%.

What factors contributed to its popularity and how your business can benefit from such systems — read on to find the answers.

What automated visual inspection systems are and how they work

Automated visual inspection (AVI) systems are sophisticated solutions that leverage cameras, sensors, lighting, and computer vision algorithms to automatically examine products, components, or materials on production lines for various defects, inconsistencies, and quality issues. Such systems are able to flag surface defects, dimensional inaccuracies, and foreign objects, making sure the products meet the highest quality standards.

What’s under the hood of such systems? Here’re the steps describing the whole process.

Product positioning

First and foremost, to be thoroughly inspected, products should be positioned correctly and consistently along a production line. Correctly here means the way physical sensors (magnetic or optical ones) and cameras would be able to detect the item, capture its particular pasty, and send the corresponding signals to the AI system.

Image acquisition

By leveraging special engineered lighting and industrial cameras, automated visual inspection systems capture high-resolution digital images of items. Optimized LED arrays like ring, dome, or backlighting are usually used to minimize glare / shadows and maximize the contrast of defects. The camera type is chosen depending on the task. For stationary parts, area scans are perfect, for fast-moving products, line scans are ideal, and for height volume measurements, 3D cameras are well-suited.

Image processing

The obtained raw images might be distorted by factory environments, and processing is the phase where they’re cleaned and converted into a suitable format for further analysis. This is done through:

- Denoising and filtering through algorithms like Gaussian or Median means eliminating pixel noise and artifacts without blurring critical edges.

- Normalization includes adjusting brightness and contrast to ensure consistency across batches.

- Binarization involves converting grayscale images into binary (black and white) to clearly isolate products from their background.

- Geometric correction. If there are any distortions caused by lens angles or some item misalignment on the conveyor belt, this stage fixes that.

Feature extraction

After images are processed, AI and computer vision algorithms proceed to feature extraction. This means converting massive amounts of raw pixel data into a structured set of characteristics such as specific landmarks, edges (boundaries of a part), corners (junctions of edges), colors, shapes, patterns, and textures (brushed metal or fabric). As a result, only the most informative data is kept for further analysis.

AI-powered analysis

This phase comprises object detection and recognition, i.e. locating various objects within the image and classifying them based on learned models. The extracted features are then compared against the reference standards or models to detect anomalies in items such as scratches, dents, cracks, discoloration, or missing parts. After that, defects are classified based on severity, type, or location, which helps prioritize repairs or rejections.

Integration and action

The image analysis is followed by triggering a physical or digital response in real time. Defective items are removed from the line by robotic tools. Also, detailed reports are automatically generated, featuring analysis results, images, metadata. All the information is stored in systems like ERP for transparency and traceability. The analyzed data is fed back to the AI model so that it could be continuously retrained and adapted to new defect types or production drifts.

Automated quality inspection: Top benefits

Regarding the industry you’re in, visual inspection automation will bring you tangible business value with a 100% guarantee.

- Superior accuracy and precision. Automated visual inspection presupposes detecting microscopic flaws (for example, hair-wide scratches or pinhead-size misalignments) that human workers fail to notice. This results in higher quality products going into production (with accuracy often exceeding 99%) as well as fewer false positives or negatives.

- Better speed. Automated visual inspection systems are able to process images in milliseconds (usually 15–50 ms), a way faster than in manual methods. Besides, a single system gauges multiple quality parameters (dimensions, surface quality, label accuracy, etc.) simultaneously, eliminating the need for sequential human stations.

- Increased productivity. Unlike human inspectors, automated visual inspection systems don’t have fatigue, boredom, or subjectivity, and they can operate 24/7 across all shifts. Operation around the clock leads to streamlined workflows, faster decision-making, and fewer bottlenecks, resulting in increased overall productivity and throughput.

- Slashed costs. Visual inspection process automation minimizes errors and notably reduces the number of operators needed per shift (down to just one supervisor), thus lowering labor costs. As defects are identified earlier in the process, manufacturers reduce expensive rework, scrap, and warranty claims, while minimizing overall waste and downtime.

- Better worker safety. Being able to work in hazardous or hard-to-reach areas, automated visual inspection systems minimize the exposure of human workers to dangerous environments, including offshore rigs, high-temperature areas, or zones with chemical exposure. This improves overall safety and decreases the number of workplace accidents.

- Improved traceability and compliance. Automated visual inspection solutions seamlessly document all inspection data, creating digital records and audit trails. Such detailed logs are important for facilitating audits, ensuring strict regulatory compliance, and getting industry-specific certifications.

Move your business to new heights of efficiency

How to integrate automated visual inspection into your workflows: Industry-specific use cases

Depending on your industry and specific business needs, you can implement automated visual inspection. Here are some use cases to make up your mind.

Medicine

In this domain, automated visual inspection finds its feet in the following situations:

- Pill damage detection. Underpinned by powerful AI mechanisms, visual inspection systems can easily and rapidly detect chips, scratches, and spots as small as 50 microns. Any deviations in size, form, and quantity are detected and flagged.

- Chemical verification. With the usage of hyperspectral imaging (NIR), AI systems analyze the actual chemical composition (API presence) of pills on the line, detecting those that fail to meet the correct drug concentration levels. All this is done without destroying the very sample.

- Medical device assembly inspection. To ensure compliance with strict standards like ISO 13485 and FDA QSR, advanced visual systems timely detect and address scratches, dents, imperfections, and failures in critical connections (like improper airflow in respiratory devices).

Public safety

Fueled by powerful cameras and sophisticated analysis tools, automated visual inspection systems perform the following functions:

- Threat detection. Visual intelligence is able to detect possible public threats and alert the required personnel before a breach occurs. This includes identifying weapons (knives, guns, etc.), abnormal person behavior (loitering in restricted zones, luggage abandonment, erratic running, etc.), as well as fugitives or missing persons through accurate face recognition (despite masks or glasses). On top of that, AI-powered systems can make the most of cameras (ground-based, aerial, satellite) and convolutional neural networks to identify early signs of fire, smoke, flood, thus preventing natural hazards.

- Public traffic management. AI systems use advanced object recognition to continuously monitor highways for stopped vehicles, illegal crossings, debris, wrong-way drivers, anomalous maneuvers, and other unusual patterns. This and general information about traffic density, speed, and congestion levels help identify bottlenecks, timely alert emergency services, and prevent accidents.

Commerce

No matter if you have an online platform or physical stores, automated visual inspection will help you reap the benefits.

- Product damage detection. With the help of high-resolution cameras and sensors, AI systems identify physical defects in goods and packaging, including dents, punctures, or compromised seals, thus preventing the acceptance of damaged inventory into the warehouse. On top of that, AI is able to analyze structural integrity, detecting broken shrink wrap on pallets.

- Inventory auditing is also performed automatically. Computer vision-enabled systems use cameras, sensors, and powerful analytics tools to scan and analyze inventory items on shelves and spot discrepancies (including missing, misplaced, or incorrectly labeled items). If you’re in the food industry, you can automate the process of product freshness monitoring by identifying discoloration, expired products, etc.

Automotive industry

Automated visual inspection revamps the automotive sector, helping manufacturers increase efficiencies and enable proactivity.

- Surface defect identification comprises body panel quality checks (detecting dents, scratches, paint imperfections, etc.), paint quality control (identifying runs, drips, uneven coating, color mismatches, etc), window inspection (spotting cracks, chips, etc.), and interior inspection (including the analysis of cleanliness and proper installation of interior parts).

- Assembly verification. AI makes sure critical parts (even small ones like bolts, wiring harness clips, or gaskets) are correctly oriented. It also helps automate processes such as weld and fastener integrity, gap and flush measurement (ensuring aerodynamic efficiency and safety), and EV battery stacking (to prevent thermal runaway risks).

Gas and oil sector

In this sector, computer vision-based inspection has also found its feet:

- Pipeline monitoring. Computer vision enables around-the-clock infrastructure surveillance. To wit, drones and satellites equipped with AI and sensors can identify gas plumes and methane leaks invisible to the human eye. ML algorithms can also detect sub-millimeter cracks, rust, and surface deformations in pipelines / storage tanks. Besides, drone-enabled encroachment monitoring facilitates spotting unauthorized construction, illegal tapping, or vegetation overgrowth.

- Exploration and production. With automated visual inspection, you can optimize high-risk operations and notably improve exploration accuracy. By analyzing 2D and 3D seismic datasets, AI systems can pinpoint reservoirs, eliminating costly “dry wells”. With the advanced analysis of downhole camera footage, AI tools spot rock formations, thus optimizing drilling. Furthermore, drones can thoroughly inspect hard-to-reach areas like under-deck structures without any production shutdowns.

Automated visual inspection implementation with Aetsoft

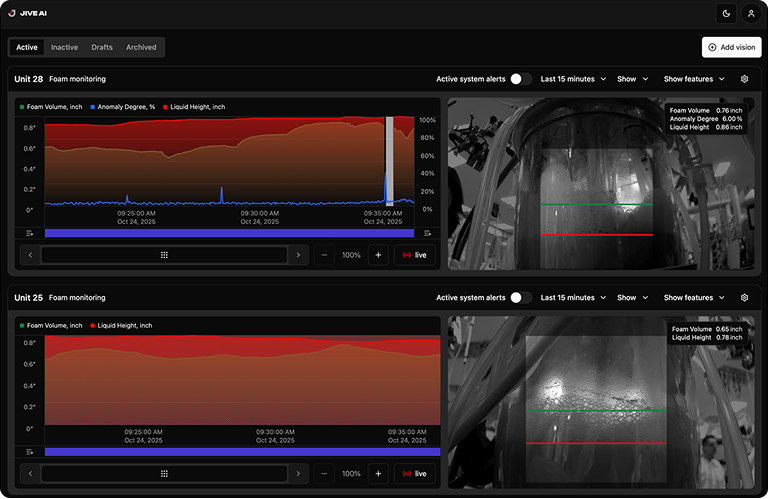

Underpinned by years of expertise in artificial intelligence and machine learning, we at Aetsoft, developed a proprietary AI platform for cognitive vision to address your most complex visual inspection needs.

Our custom solution has a modular and hardware-agnostic architecture, which makes it perfect for working with existing or new cameras systems and sensors. So whether you need a solution from the ground up or just partial implementations, we’ve here to assist.

Our pre-built AI modules enable rapid time to market, interactive UI and operational widgets ensure great user experiences, and advanced analytics with centralized dashboards provide traceability and transparency for both engineers and stakeholders.

You can implement our visual system on edge, cloud, or hybrid setups. We also ensure robust industrial integrations and automation through OPC-UA, REST, MQTT connectivity, easy-to-configure alert logic, and IP67-ready hardware options.

Our system can be tailored to various industries, so contact us now to discuss your particular case and business needs.